With a worldwide reputation for excellence, DEKOMTE manufactures fabric and stainless steel expansion joints for all applications within a thermal power station otherwise known as a steam boiler plant. This offers varying technical standards to suit the technical requirements, maintenance cycles and budgets for each joint.

Boilers and pressure parts continually subject the ducting to extreme stress and fatigue, with the expansion joint being the focus point and relief. We can offer a solution for a wide range of thermal power applications.

In many power plants, the failure and replacement of expansion joints is considered routine maintenance. Weld repairs to steel parts and duct cracking become common place during outages.

A complete solution, encompassing the whole scope of duct, frame, adjacent insulation and expansion joint, will provide a reliable, maintenance-free solution with a longer lifespan. Depending on the site’s operating conditions, a DEKOMTE solution can offer lifespans of up to 25 years.

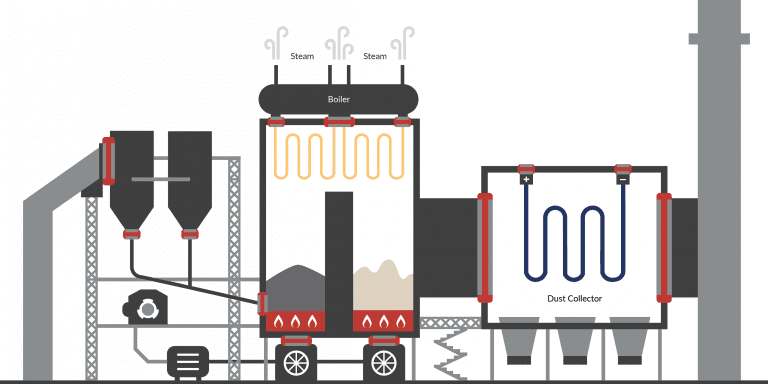

Conventional Oil / Coal-Fired Boilers

Conventional boiler power plants burn predominantly fossil fuels of coal, oil or gas. However, in recent years many plants have been converted to fire using additional biofuels with renewable credentials. Boiler designs have not significantly changed in 100 years, with the basic thermal physics based on the Rankine cycle. Flue gas treatment and scrubbing systems are the main area of development and have increased usage of expansion joint systems.

Increasing the combustion temperatures in supercritical design boilers adds some complexity in achieving reliable expansion joints, particularly as the movements can get much larger.

Expansion joints are incorporated between systems and components to provide low tension thermal expansion compensation. Further areas of utilisation include sound absorption, muffling and vibration damping and fire prevention. This is in addition to adjustment of assembly inaccuracies and varying settling patterns of foundations.

DEKOMTE has designed expansion joints for numerous high technically demanding environments. This includes from extreme temperatures of above 900ºC / 1650ºF, to below 50ºC / 120ºF. Large movements and tight installation areas pose interesting challenges, which we handle every day.

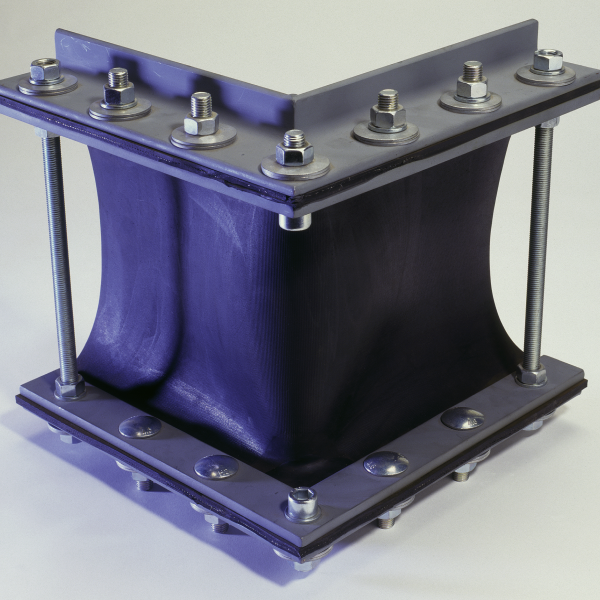

FKM and EPDM joints are essential in low temperature ducting, where dew point may occur. The sealing of the duct with a stable and durable rubber joint is necessary, particularly in FGD systems where acid dew point may be prevalent. Moulded corners and formed joints give reliable operation with minimal fatigue usage and longer life with no creasing or folding.

Fabric Expansion Joint Applications:

- Ash hopper

- BOFA – Boost Over Fired Air Ducts

- Boiler penetrations and duct connections

- ESP – Electro-Static Precipitation

- FGD – Flue Gas Desulphurisation

- Main boiler ducting

- SCR – Selective Catalytic Reduction

- Ventilation ducts

Metallic Expansion Joint Applications:

- Air Supply / Plant Air

- Flue Gas

- High Pressure Pipework

- Oil Connections

- Steam Piping and Penetrations

DEKOMTE offers varying technical solutions to suit the technical requirements, maintenance cycles and budgets for each location of the joints. The large scale systems necessary for desulphurisation of flue gases have created highly demanding technical and environmental requirements for expansion joints. The large sizes and consistent quality require a competent supply partner like DEKOMTE.

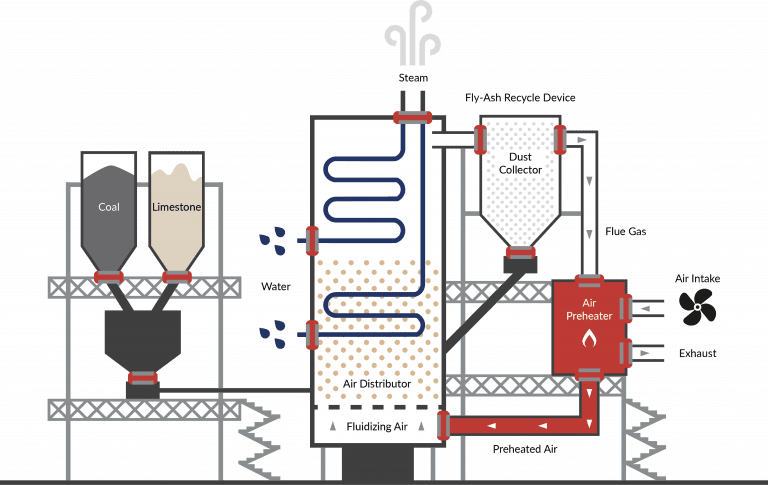

Circulting Fluidised Bed (CFB) Boilers

Fluidised Bed Combustion (FBC) is a combustion technology used to burn solid fuels. In its most basic form, fuel particles are suspended in a hot, bubbling fluid bed of ash and other particulate materials (for instance, sand, limestone, etc). Through which jets of air are blown to provide the oxygen required for combustion or gasification.

The resultant fast and intimate mixing of gas and solids promotes rapid heat transfer and chemical reactions within the bed. FBC plants are capable of burning a variety of low-grade solid fuels, including most types of coal and woody biomass, at high efficiency and without the necessity for expensive fuel preparation (e.g. pulverising). In addition, for any given thermal duty, FBCs are smaller than the equivalent conventional furnace. This means that they may offer significant advantages over the latter in terms of cost and flexibility.

FBC reduces the amount of sulphur emitted in the form of SOx emissions. Limestone is used to precipitate out sulphate during combustion, which also allows more efficient heat transfer from the boiler to the apparatus used tocapture the heat energy (usually water tubes). The heated precipitate coming in direct contact with the tubes (heating by conduction) increases the efficiency. Since this allows coal plants to burn at cooler temperatures, it also causes increased Polycyclic Aromatic Hydrocarbon (PAH) emissions. FBC boilers can burn fuels other than coal, and the lower temperatures of combustion have other added benefits as well.

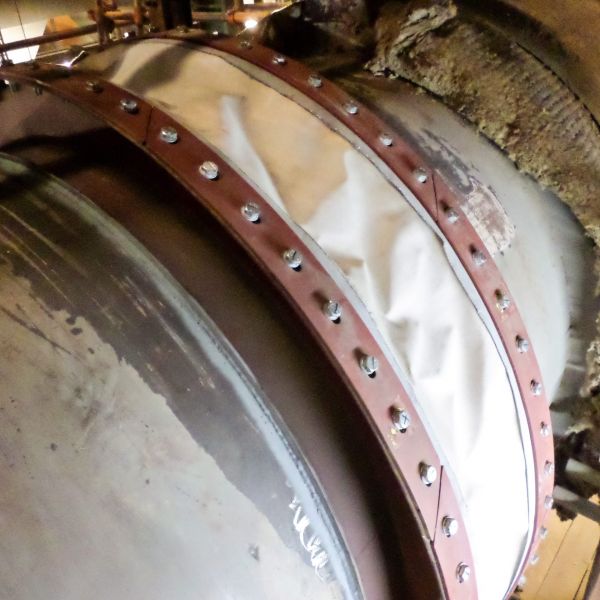

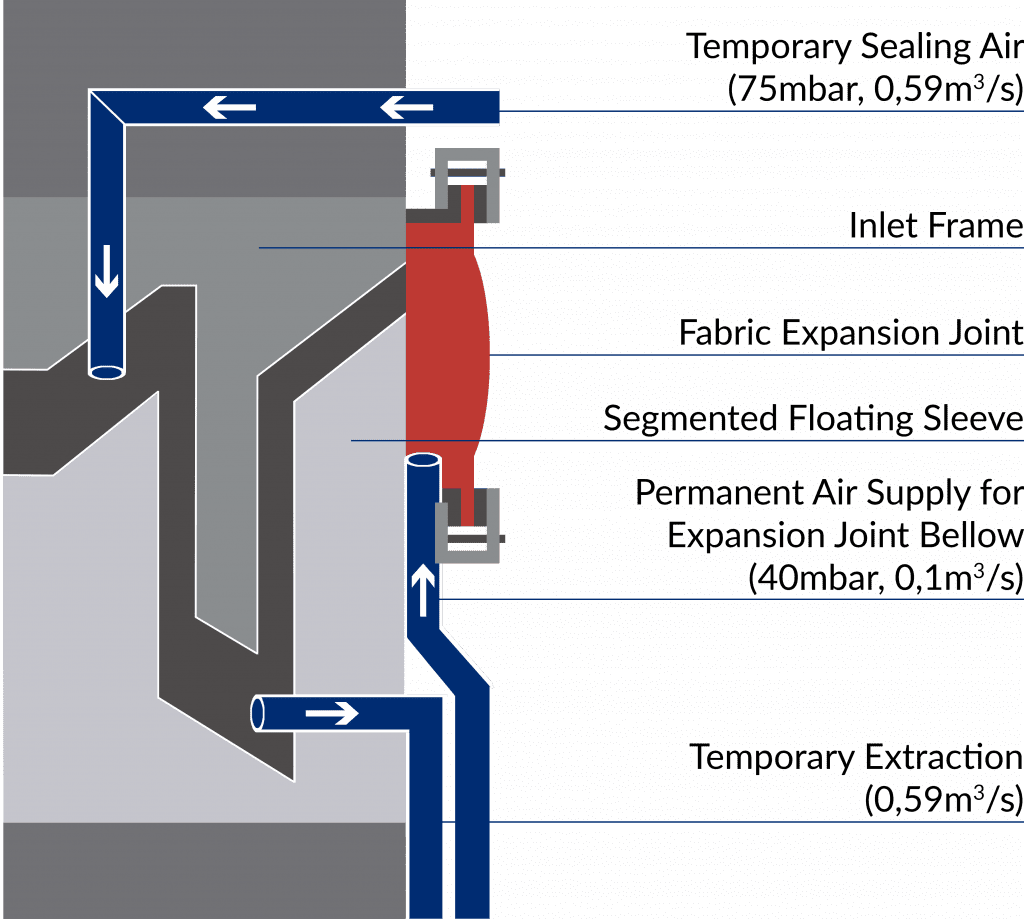

The critical problem with expansion joints is the temperature variance and gradients. Dust on the steel parts can cause flash and cool spots, leading to shortening the life of the joint. By using general purpose site utility air, a sealing cushion of air can be created at the joint. This, in turn, eliminating dust ingress and maximising life.

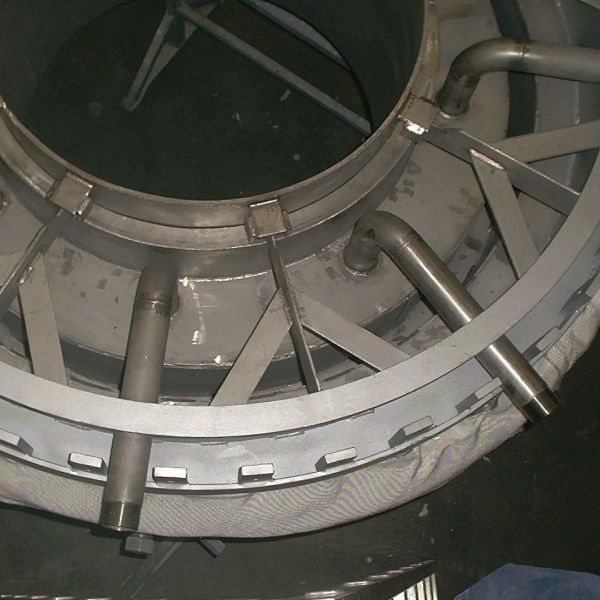

In a CFB boiler, the outlet from the cyclone requires a sophisticated expansion joint solution that uses sealing air to avoid ash entering into the breach space required for the movement. The approach of DEKOMTE to look at the larger engineering challenge demonstrates an integrated design concept that delivers value and lifetime to the end client.

Biomass and Waste to Energy

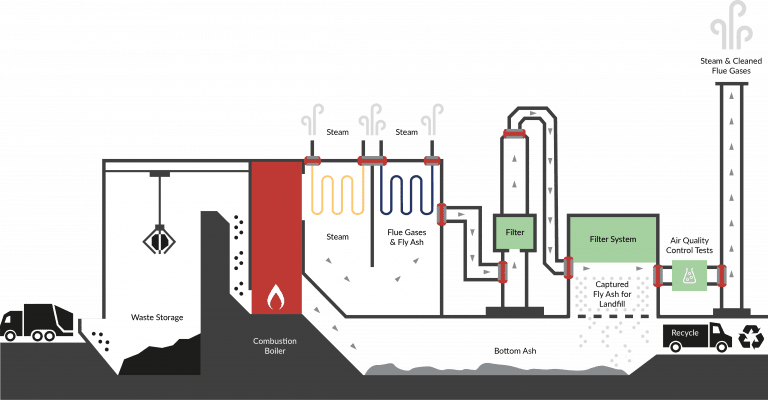

A waste-to-energy plant is a waste management facility that combusts wastes to produce electricity. This type of power plant is sometimes called a trash-to-energy, municipal waste incineration, energy recovery, or resource recovery plant. The principle operation of this facility is the same as a conventional boiler Rankine cycle design.

Biomass is an industry term for getting energy by burning wood and other organic matter. Burning biomass releases carbon emissions, but has been classed as a renewable energy source in the EU and UN legal frameworks. This is because plant stocks can be replaced with new growth. It has become popular among coal power stations, which switch from coal to biomass in order to convert to renewable energy generation without wasting existing generating plant and infrastructure. As an energy source, biomass can either produce heat directly via combustion, or indirectly after converting it to various forms of biofuel. Conversion of biomass to biofuel can be achieved by different methods. These methods are broadly classified into thermal, chemical, and biochemical.

Waste-to-Energy or Energy-from-Waste is the process of generating energy in the form of electricity and/or heat from the primary treatment of waste. Most WTE processes produce electricity and/or heat directly through combustion, or produce a combustible fuel commodity, such as methane, methanol, ethanol or synthetic fuels.

Fabric Expansion Joint Applications:

- Bag house

- Boiler grate

- Boiler penetrations and duct connections

- Main boiler ducting

- Ventilation ducts

The combustion of organic material such as waste with energy recovery is the most common WTE implementation. All new WTE plants in OECD countries incinerating waste (residual MSW, commercial, industrial or RDF) must meet strict emission standards, including those on nitrogen oxides (NOx), sulphur dioxide (SO2), heavy metals and dioxins. Hence, modern incineration plants are vastly different from old types, some of which neither recovered energy nor materials.

Ash and corrosion within the ducting poses a serious challenge to the life and gas tightness of fabric joints within the biomass plant. Our utilisation of increased internal protection and the latest fabric and pillow construction techniques are essential for reliability.

CCGT Power Plant – HRSG Combination Side Wall Penetration Seal in Poland

CCGT Power Plant – HRSG Combination Side Wall Penetration Seal in Poland Conventional Coal Power Plant – Ash Hopper Fabric Retrofit in the USA

Conventional Coal Power Plant – Ash Hopper Fabric Retrofit in the USA Fluidised Bed Boiler Power Plant – Cyclone to Downcomer Air Sealing Solution in Czech Republic

Fluidised Bed Boiler Power Plant – Cyclone to Downcomer Air Sealing Solution in Czech Republic