fabric expansion joints

Fabric expansion joints are suited for gaseous media, such as air, exhaust gases and solvent fumes, as well as for operation below dew point (also involving substances with certain concentration of acids), also with abrasive enriched gases (e.g. coal or cement dust).

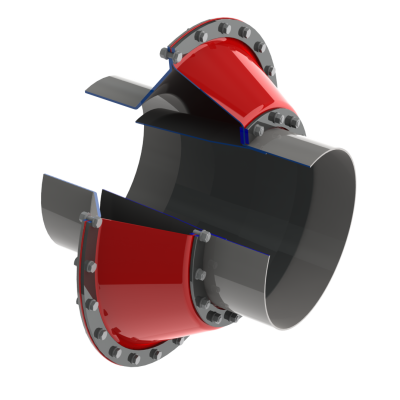

Due to their modular design, fabric expansion joints adjust especially well to different requirements (e.g. critical sealing requirements, frequent temperature and pressure variations), and therefore, cover a very wide spectrum of applications.

The high quality materials as well as the technical experience in designing and manufacturing assure the long life and durability of DEKOMTE fabric expansion joints.

1

Applications: Standard application flat band joint suitable for ventilation...

2U

Applications: Universal application for increased tightness requirements at....

10

Applications: Suitable as an exhaust expansion joint design for applications...

3W

Applications: Long life time at dynamic temperature loads in gas turbine plants...

ME

Applications: Acceptance of higher movements at very high temperatures...Fabric Expansion Joints

DEKOMTE supplies quality fabric expansion joints, made from many different materials. In principle, fabric expansion joints are best for gaseous media, such as air, exhaust gas and solvent fumes, particularly for operation below the dew point, in acidic environments, or for abrasive exhaust gases (e.g. containing coal dust).

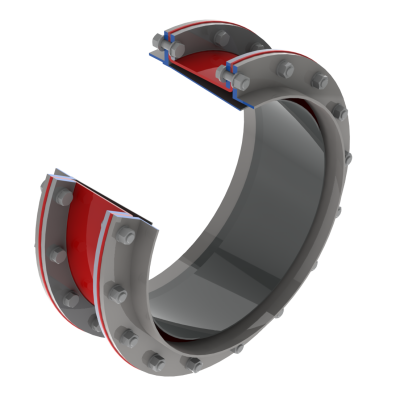

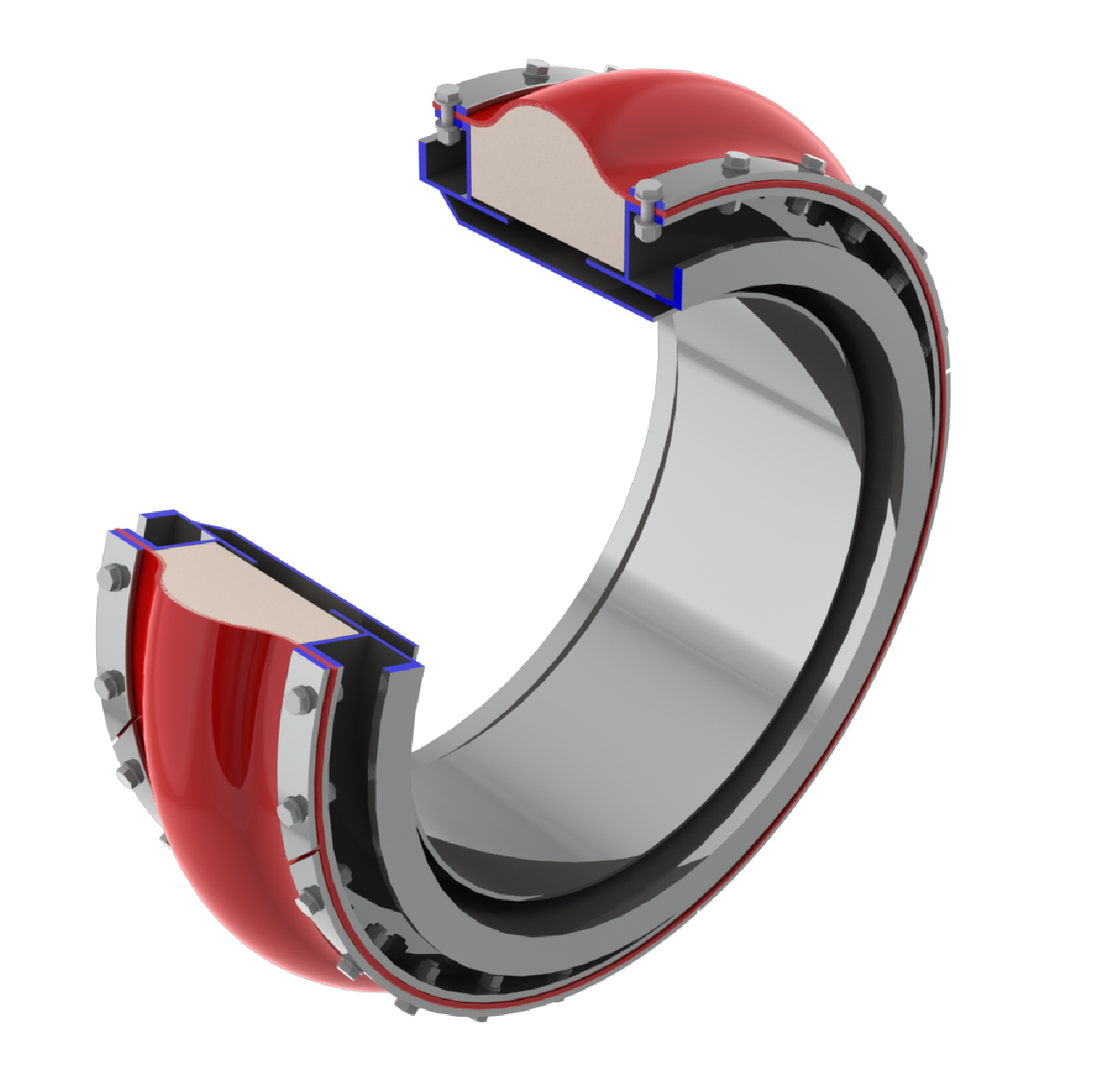

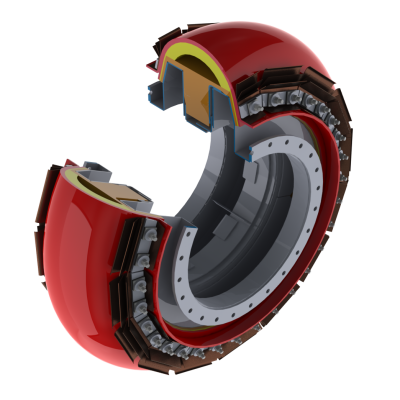

Fabric expansion joints are often multi-layer systems, consisting of:

- Temperature and corrosion-resistant insulating fabrics

- Gas impermeable films, including:

- Foils – stainless, aluminium or Inconel

- PTFE and composites

- Silicone and rubber

- UV and water resistant materials for external protection

Part of the construction must also consider the supporting mechanical layers to give strength for maintaining the shape and resist pressure (normally internally, but also under negative pressure).

Repairs & Maintenance

An advantage of fabric expansion joints is the ability to patch, repair and replace in sections, thus minimising the downtime or outage. DEKOMTE service approach gives reliable technical advice on what can be repaired and what must be replaced. Considerations to be taken are:

- Damage can be repaired in spot cases to bridge to the next scheduled outage

- Cold-casing application joints can be repaired with low risk and good reliability

- Reliability of repairs can be difficult to achieve in high temperature applications

When an inspection is made, the fabric replacement can be planned to coincide with outage schedules. The upgrading of materials, composition, fixing systems or internal parts can give an important impact on longer life and more durable expansion joints.

A thorough evaluation of the adjacent ducting is required to minimise modification to the duct or steel parts.

The overall form and shape of the joint is designed and constructed solely for the allowable movements required. Caution should be taken in any additional movement flexibility outside the specified movement criteria.

Movements

Axial Movement Compression

Axial Movement Extension

Lateral Movement

Angular Movement

QUALITY.

ASSURED.

Make contact today to help you choose the right solution

24/7, 365 day support for all your inspection, assessment or installation requirements.

GE 6FA CCGT Power Plant – GT Exhaust Expansion Joint in England

GE 6FA CCGT Power Plant – GT Exhaust Expansion Joint in England GE 9FA CCGT Power Plant – HRSG Inlet High Cycling Expansion Joint in Wales

GE 9FA CCGT Power Plant – HRSG Inlet High Cycling Expansion Joint in Wales