DESIGN AND ENGINEERING

Design and engineering integration at an early stage can identify the best overall solution for a trouble-free system. Reliability, performance and the technical and commercial guarantee requirement, means that DEKOMTE has developed into a complete turnkey provider.

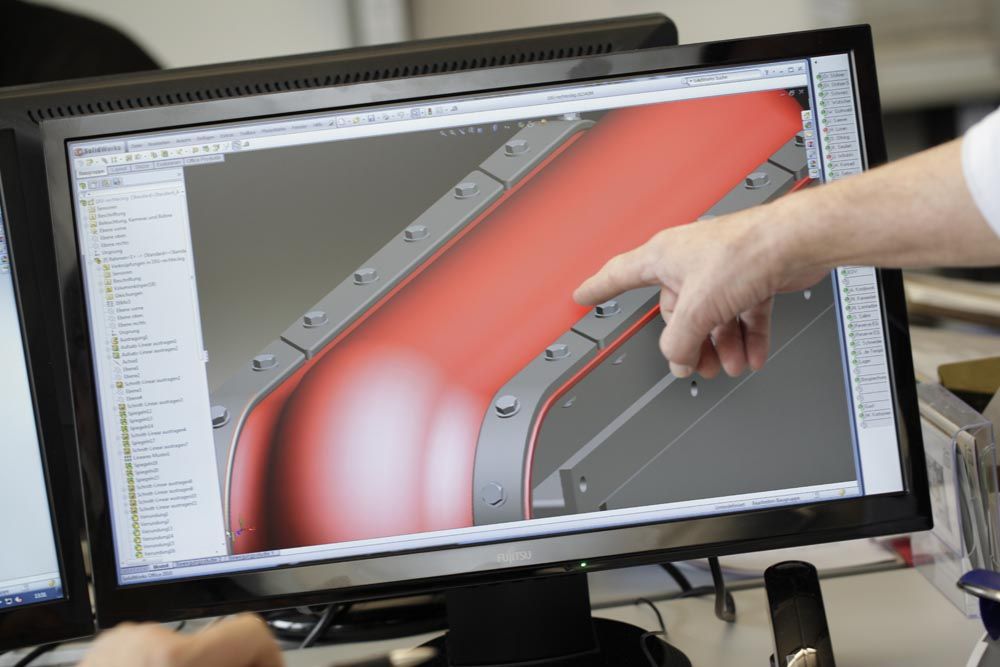

Design Tools

DEKOMTE pushes the boundaries of product development with the latest computer and industry best practice tools and procedures.

The discerning use of Finite Element Analysis (FEA) and Computational Fluid Dynamics (CFD), together with 2D and 3D design software, allows a correlation of on-site empirical experience and theoretical models. The formulation of specifications, tenders and design critique are also offered as an independent technical service.

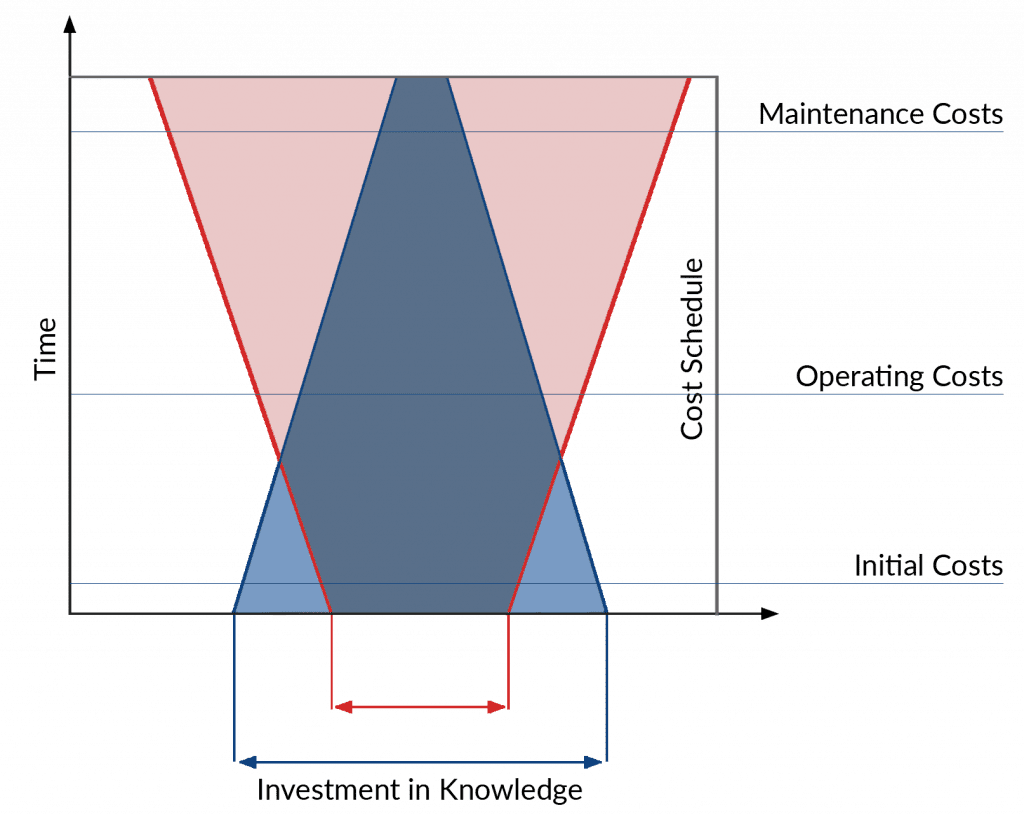

Economical Value Analysis

DEKOMTE are able to offer varying levels of technical standard to reach a budget and lifetime required by the customer.

DEKOMTE recommend a life cycle value analysis to evaluate the total cost of ownership for an end user. The OEM choices which compare the quality, technical level and cost, must be balanced against the long term function required by a plant. The costs associated with maintenance far outweigh the initial capital cost of equipment. DEKOMTE design and quality philosophy can give significant cost savings by an improved longer life initial solution.

Scope of Supply

The scope of design and engineering responsibility is a key aspect of DEKOMTE philosophy for an integrated solution to the adjacent duct; this ensures no weakness in the steel frame, liner plate or insulation system.

A metal frame, flow plate, liner system, backing bars, fixings and insulation all form part of the scope that creates a reliable expansion joint. DEKOMTE is able to consider the impacts of turbulent flow, pressure variations, vibration to the expansion joint and the surrounding environment.

Formed Solutions

DEKOMTE manufacture bespoke tailor-made solutions, utilising moulds and forms that create an expansion joint to a desired shape. The purpose of a mould is to allow movements to take place without any creasing or folding of materials.

A smooth and formed joint maintains a constant and even surface temperature which reduces the thermal stress and any fatigue to the materials and important gas membrane. Formed joints are essential in all high movement requirements, where creasing causes rapid material degradation and failure.

Make contact today to help you choose the right solution

24/7, 365 day support for all your inspection, assessment or installation requirements.