Hotspot Repair Technology

Whilst regular insulation repairs and maintenance can be intrusive, laborious and time-consuming, pumpable insulation is an alternative solution that lowers cost and shortens downtime.

DEKOMTE can repair missing insulation pockets and hot areas by injecting liquid insulation from the outside while the unit is running.

What is Pumpable Insulation?

Pumpable insulation consists of short bio-soluble fibres that have been blended with binders to form a paste-like consistency mastic that can be pumped into a cavity.

A pneumatically-driven pump consisting of a pneumatic motor, hopper, pressure regulator, gauge and a 20m delivery hose is used to inject the insulation material.

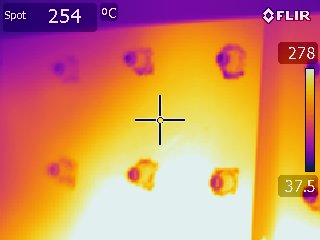

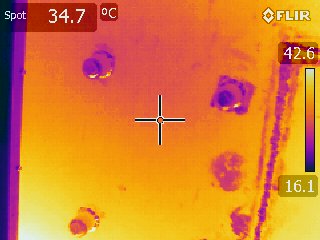

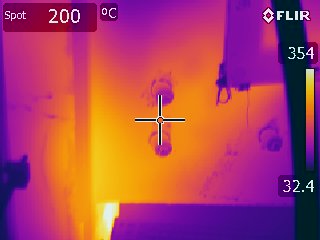

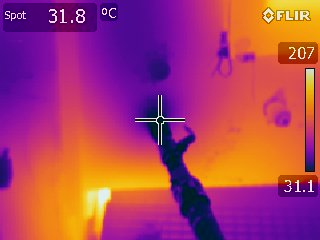

- Sockets are welded at 250mm intervals to form an array / matrix around the hot spot area. Using the array of sockets as a template, the outer casing is drilled to create a flow-path for the mastic insulation.

- The mastic delivery hose is connected to each socket in turn, and the mastic material is pumped into the cavity while simultaneously

being monitored by a thermal imaging camera. - Once the insulation has been successfully injected into the cavity, the sockets are capped off with a hexagon plug.

Pumpable Insulation Applications

- GT casing

- GT Exhaust Diffuser

- Penetration Seals

- HRSG Casing

Causes of Insulation Loss

- No liner

- Liner plate damage

- Gas flow under liner (by distortion or gaps in the liner)

- Compacting of insulation

- Degradation of insulation (by moisture or vibration)

Effects of Insulation Loss

- Casing cracks leading to gas leakage

- Temperature-induced material fatigue

- Decreased efficiency

- All effects cause adjacent safety and environmental concerns

- Increased maintenance costs

During an annual inspection, one of our customers discovered they had poor insulation in the internal liner plates of their GT Exhaust duct. The plant had repaired the liner plate issues and renewed the insulation, but the location was still showing hotspots.

The hot spot is created by movement or breakdown of the mineral wool and ceramic fibres that leaves a void in the insulation. Using a small team of site engineers and Unifrax Isofrax insulation material, this issue can be solved quickly and economically.

Typical Casing Insulation

Low thermal conductivity (600ºC – 0.09 W/mK)

Use limit 1200ºC / Melting point >1500ºC

Dry density 96-128kg/m3

Resistant to flue gas velocities up to 20m/s

Pumpable Insulation

Low thermal conductivity (600ºC – 0.09 W/mK)

Use limit 1200ºC / Melting point >1500ºC

Wet density 1090kg/m3 / Dry density 270kg/m3

Resistant to flue gas velocities up to 20m/s

Casing Repairs

DEKOMTE also offers casing repairs, liner modifications and new attachment solutions. These are aimed at maintaining casing temperatures for a longer life.

Make contact today to help you choose the right solution

24/7, 365 day support for all your inspection, assessment or installation requirements.