Springerville Generating Station (SGS) is a state of the art coal-fired power plant that will ensure the future of energy in Arizona. The plant consists of four units: units 1 and 2 generate a capacity of 760 MW, unit 3 adds 400 MW and unit 4 adds another 400 MW. The site also has two BBC DS 50 steam turbines.

| Total Output: |

1560 MW |

| Date Operational: | 1985 |

| Location: | Arizona, USA |

| Primary Fuel: | Coal |

The Springerville power plant had an original dipper plate into a water trough installed to seal the bottom of the boiler to the ash hopper.

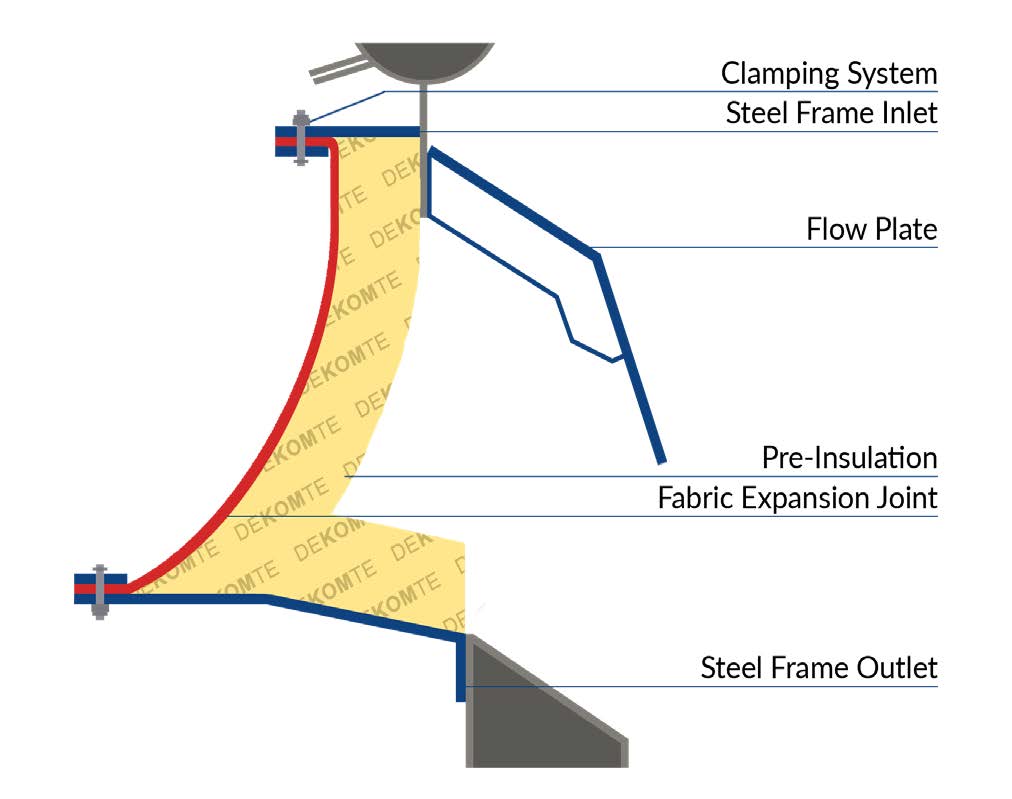

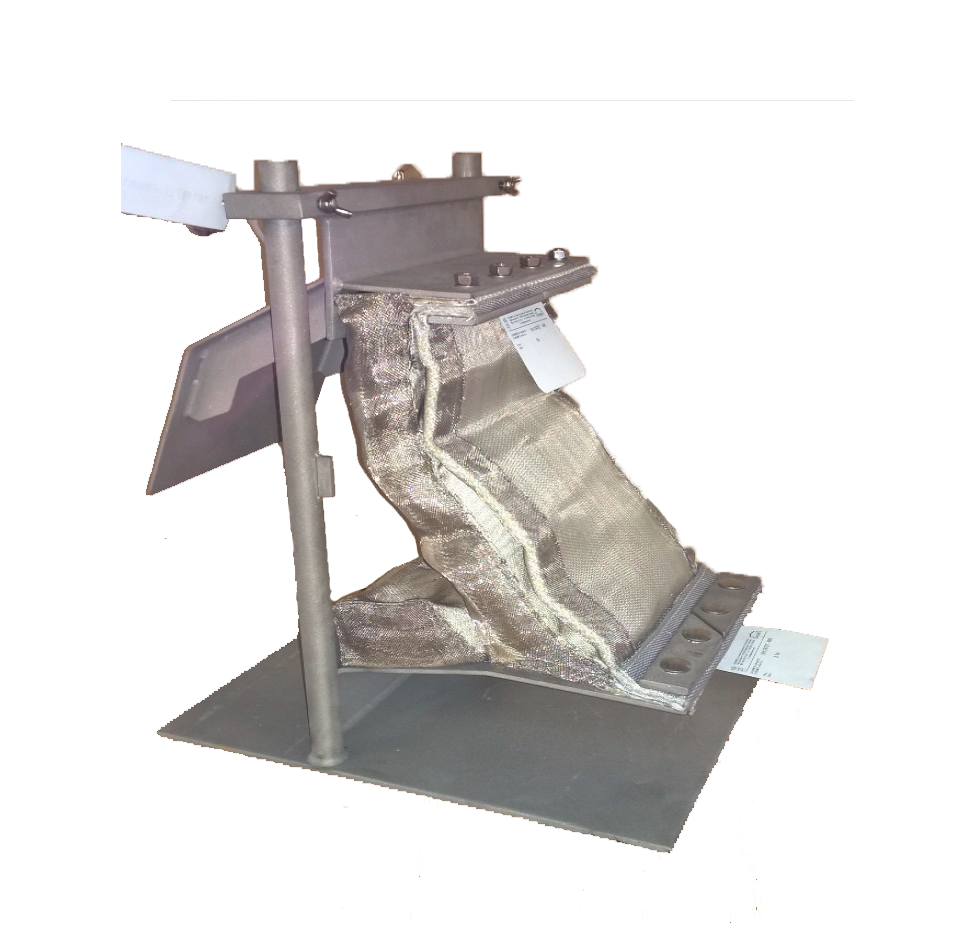

The Springerville ash hopper dipper trough was upgraded with a DEKOMTE dry seal expansion joint retrofit, incorporating a new drip shield, flow plate, fabric joint, backing bars and inlet & outlet frames. By offering a complete product scope, DEKOMTE can assure long life and reliability in service. The fabric solution gave gas tightness, which maintains the boiler efficiency and integrity. Performance of the unit was critical to the combustion efficiency in the last years of the plant’s operation.

| Dimensions Inside: |

21211mm x 5095mm |

| Boiling Operating Temperature: | 316°C |

| Maximum Temperature: | 482°C |

| Movement: | Axial: -241mm Lateral: 64mm |

24/7, 365 day support for all your inspection, assessment or installation requirements.

© DEKOMTE de Temple Kompensator-Technik GmbH – all rights reserved

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-advertisement | 1 year | Set by the GDPR Cookie Consent plugin, this cookie is used to record the user consent for the cookies in the "Advertisement" category . |

| cookielawinfo-checkbox-analytics | 1 year | Set by the GDPR Cookie Consent plugin, this cookie is used to record the user consent for the cookies in the "Analytics" category . |

| cookielawinfo-checkbox-functional | 1 year | The cookie is set by the GDPR Cookie Consent plugin to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-marketing | 1 year | This cookie is set by the GDPR Cookie Consent plugin to store the user consent for the cookies in the category "Marketing". |

| cookielawinfo-checkbox-necessary | 1 year | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-non-necessary | 1 year | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Non Necessary". |

| cookielawinfo-checkbox-others | 1 year | Set by the GDPR Cookie Consent plugin, this cookie is used to store the user consent for cookies in the category "Others". |

| cookielawinfo-checkbox-performance | 1 year | Set by the GDPR Cookie Consent plugin, this cookie is used to store the user consent for cookies in the category "Performance". |

| cookielawinfo-checkbox-uncategorized | 1 year | The cookie is set by the GDPR Cookie Consent plugin to record the user consent for cookies in the category "Uncategorized". |

| CookieLawInfoConsent | 1 year | Records the default button state of the corresponding category & the status of CCPA. It works only in coordination with the primary cookie. |

| elementor | never | The website's WordPress theme uses this cookie. It allows the website owner to implement or change the website's content in real-time. |

| trp_language | 1 month | No description available. |

| viewed_cookie_policy | 1 year | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |

| viewed_cookie_policy | 1 year | The GDPR Cookie Consent plugin sets the cookie to store whether or not the user has consented to use cookies. It does not store any personal data. |

| Cookie | Duration | Description |

|---|---|---|

| _ga | 2 years | The _ga cookie, installed by Google Analytics, calculates visitor, session and campaign data and also keeps track of site usage for the site's analytics report. The cookie stores information anonymously and assigns a randomly generated number to recognize unique visitors. |

| _ga_* | 1 year 1 month 4 days | Google Analytics sets this cookie to store and count page views. |

| _ga_Z46495WQ2B | 2 years | This cookie is installed by Google Analytics. |

| CONSENT | 2 years | YouTube sets this cookie via embedded youtube-videos and registers anonymous statistical data. |

| Cookie | Duration | Description |

|---|---|---|

| VISITOR_INFO1_LIVE | 5 months 27 days | A cookie set by YouTube to measure bandwidth that determines whether the user gets the new or old player interface. |

| YSC | session | YSC cookie is set by Youtube and is used to track the views of embedded videos on Youtube pages. |

| yt-remote-connected-devices | never | YouTube sets this cookie to store the video preferences of the user using embedded YouTube video. |

| yt-remote-device-id | never | YouTube sets this cookie to store the video preferences of the user using embedded YouTube video. |

| yt.innertube::nextId | never | This cookie, set by YouTube, registers a unique ID to store data on what videos from YouTube the user has seen. |

| yt.innertube::requests | never | This cookie, set by YouTube, registers a unique ID to store data on what videos from YouTube the user has seen. |

| Cookie | Duration | Description |

|---|---|---|

| DEVICE_INFO | 5 months 27 days | No description |

| show_preloader_once | session | No description |